- Development of Sm-Fe-N bulk magnets with the highest-level (BH)max

- Detailed microstructure in high coercivity Zn-bonded Sm-Fe-N magnets

- Development of the Ta coated anisotropic Nd-Fe-B magnetic powders for bonded-magnets

- Achievement of Mn-diffused Sm-Fe-N core-shell powders with high magnetization and thermal stability

- Achievement of high performance Sm-Fe-N bulk magnets

- Achievement of high coercivity Zn-bonded Sm-Fe-N permanent magnets

- Development of FeCo based anisotropic films

- Preparation of high-coercive FeCo based nanoparticles

- High-Pressure Synthesis of New Magnetic Compound in Mn-Li-N System

- Development of Nd-Fe-B Ultrafine Powders Comparable to Single Domain Size

- Development of New Mn-based Alloys with High Coercivity

Development of Sm-Fe-N bulk magnets with the highest-level (BH)max

We fabricated the low oxygen content Sm-Fe-N/Zn composite powder by mixing the low oxygen content Sm-Fe-N powder and the low oxygen content and fine particle size Zn powder prepared by the Hydrogen-Plasma-Metal (HPMR) method. After sintering this low oxygen content Sm-Fe-N/Zn composite powders by the Spark-Plasma-Sintering (SPS), this magnet exhibited high (BH)max of 200 kJ/m3 (= 25 MGOe). This is superior property compering with previously reported values of Sm-Fe-N magnets having the same level coercivity.

- R. Matsunami, M. Matsuura, N. Tezuka, and S. Sugimoto, ”Preparation of Sm-Fe-N bulk magnets with high maximum energy product”, Journal of Magnetic Society of Japan, vol. 44, No. 3, (2020), 64-69.

https://doi.org/10.3379/msjmag.2005R003

(※Awarded the MSJ Encouragement Award)

Detailed microstructure in high coercivity Zn-bonded Sm-Fe-N magnets

We have reported the development of the Zn-bonded Sm-Fe-N magnet with high coercivity of 2.7 MA/m by using fine Zn powders with a low oxygen content in 2018, whereas the detailed microstructure in Zn-bonded Sm-Fe-N magnets has not been elucidated.

The present detailed microstructural observation of the Zn-bonded Sm-Fe-N magnet revealed that Zn diffused at the surface of the Sm2Fe17N3 phase and formed a Zn-rich region, and the ferromagnetic α-FeZn phase was surrounded by the non-magnetic Γ-FeZn phase at grain boundary.

- Masashi Matsuura, Kuniko Yamamoto, Nobuki Tezuka, and Satoshi Sugimoto, ”Microstructural changes in high-coercivity Zn-bonded Sm-Fe-N magnets”, Journal of Magnetism and Magnetic Materials, 510, (2020) 166943 1-8.

https://doi.org/10.1016/j.jmmm.2020.166943

Development of the Ta coated anisotropic Nd-Fe-B magnetic powders for bonded-magnets

It is considered that mixing anisotropic Nd-Fe-B powders with high magnetization and high coercivity and a resin is an effective method to improve the (BH)max of resin-bonded magnets.

We applied sputtering for coating Ta to fine Nd-Fe-B powders in order to suppress the binding of Nd-Fe-B powders during annealing. We obtained Ta-coated Nd-Fe-B powder by sputtering. After annealing, the coercivity increased whereas showing anisotropic hysteresis loops. Consequently, by coating Ta, we could develop the anisotropic Nd-Fe-B powders with the highly anisotropy degree of the magnetization curve comparing with the non-coated Ta powders.

- Moe Kimura, Masashi Matsuura, Nobuki Tezuka, and Satoshi Sugimoto, ”Fabrication of Anisotropic Nd-Fe-B Powders by Ta Sputtering”, Materials Transactions, vol. 60, No.5, (2019) 830-836.

https://doi.org/10.2320/matertrans.M2019003

Achievement of Mn-diffused Sm-Fe-N core-shell powders with high magnetization and thermal stability

Mn addition can enhance thermal stability of Sm2Fe17Nx based powder, however it also decreases saturation magnetization. In order to exploit the advantages of Mn addition in Sm2Fe17Nx powder while maintaining a high saturation magnetization, a structure of Sm2Fe17Nx-core/Sm2(Fe,M)17Nx-shell is promising. This is the first report to obtain such core-shell powder applying reduction-diffusion process. Sm2Fe17, Mn3O4, Sm2O3 fine powders and Ca were mixed and annealed above 840 ℃, and then the samples were nitrided and washed after reduction-diffusion process. Thus, core-shell Sm-Fe-N fine powder with Mn-enriched Sm2(Fe,Mn)17Nx shell was successfully obtained.1) Although the saturation magnetization was slightly smaller than that of Sm-Fe-N powder without Mn addition, while the coercivity of core-shell powder was higher than that of Sm-Fe-N powder without Mn. In addition, the saturation magnetization and coercivity are higher than that of Sm-Fe-Mn-N powder reported in previous papers.

- M. Matsuura, et al., “Preparation of Mn-diffused Sm-Fe-N core-shell powder by reduction-diffusion process“, Journal of Magnetism and Magnetic Materials, 471 (2019), 310-314.

https://doi.org/10.1016/j.jmmm.2018.09.084

Achievement of high performance Sm-Fe-N bulk magnets

We developed Sm-Fe-N magnetic powder with low oxygen content, and Sm-Fe-N bulk magnets were prepared from the low-O Sm-Fe-N powder by the Spark-plasma-sintering (SPS). The Sm-Fe-N bulk magnets showed high (BH)max of 179 kJ/m3 (= 22.5 MGOe). This is higher than that reported in previous works.

It is well known that Zn addition can increase coercivity of Sm-Fe-N bulk magnets. We added Zn to the low-oxygen Sm-Fe-N powder by the Arc-plasma-deposition (APD). The APD can deposit Zn fineparticles on Sm-Fe-N powder without increasing oxygen content. The low-oxygen Sm-Fe-N/Zn composite powder was sintered by SPS. The 3.3 wt% Zn-bonded Sm-Fe-N magnets showed high coercivity and high (BH)max, simultaneously, and the value was HcJ=1.1 MA/m (= 13.8 kOe) and (BH)max = 153 kJ/m3 (= 19.2 MGOe).

- M. Matsuura, et al., “Increase of energy products of Zn-bonded Sm-Fe-N magnets with low oxygen content,467,64-68.

https://doi.org/10.1016/j.jmmm.2018.07.064

Achievement of high coercivity Zn-bonded Sm-Fe-N permanent magnets

High coercivity Zn-bonded Sm-Fe-N magnets were successfully obtained using low oxygen content and fine Zn powder. The Zn powder was prepared by the Hydrogen-Plasma-Metal-Reaction (HPMR) method. The average particle size of Zn was about 0.23 µm, and the oxygen content was only 0.068 wt% (680 ppm). The Zn powder with low oxygen content could decrease oxygen content of Zn-bonded Sm-Fe-N magnets, and 15 wt% Zn-bonded Sm-Fe-N magnet showed high coercivity of 2.66 MA/m. 10 wt% Zn-bonded Sm-Fe-N magnet also showed high coercivity of 2.41 MA/m.

- M. Matsuura, et al., “High coercive Zn-bonded Sm-Fe-N magnets prepared using fine Zn particles with low oxygen content”, Journal of Magnetism and Magnetic Materials,452,243-248.

https://doi.org/10.1016/j.jmmm.2017.12.059

Development of FeCo based anisotropic films

FeCo-Ti-N films deposited on Rh(001) underlayer shows relatively high uniaxial perpendicular anisotropy constant. The Ku was 1.39 MJ/m3 and 1.15 MJ/m3 for the film with thickness of the FeCo-Ti-N layer of 7.7 and 15 nm, respectively. The crystal structure of the FeCo-Ti-N is bct, and the c/a of 1.12 for the films with thickness of 15 nm. Lattice distortion is also maintained in the thicker FeCo-Ti-N film with 62 nm, and it shows relatively high Ku value of 0.46 MJ/m3. Consequently, Ti and N addition is effective to induce lattice distortion to FeCo film and improve magnetocrystalline anisotropy.1,2,3

- M. Matsuura, et al., “Increased Uniaxial Perpendicular Anisotropy in Tetragonlly Distored FeCo-Ti-N Films”, J. Appl. Phys., 117, (2015) 17A738.

http://dx.doi.org/10.1063/1.4916763 - 河原崇範ら,“FeCo-Ti-N薄膜における格子歪と磁気異方性”, 電気学会論文誌A, Vol. 136, No.12 (2016) 804. (In Japanese).

http://dx.doi.org/10.1541/ieejfms.136.804 - 河原崇範ら,“FeCo-Ti-N系異方性薄膜における結晶構造と磁気特性の膜厚依存性”, 電気学会マグネティックス研究会資料,MAG-15-160, (2015). (In Japanese).

Preparation of high-coercive FeCo based nanoparticles

FeCo nanoparticels were deposited on SiO2 nanoparticles by Arc Plasma Deposition method. The average particle size of FeCo was 3.7 nm, and it shows anomalous high coercivity. The maximum coercivity was 600 kA/m, and the average value was 300 kA/m. Interfacial anisotropy and/or oxidation at the interface of FeCo/SiO2 can affect increasing coercivity of FeCo nanoparticles.

- D. Horiyama, et al., “High-Coercivity Fe-Co Nanoparticles Prepared by Pulsed Arc Plasma Deposition”, Materials Transaction, Vol. 57, No. 2 (2016) 207.

http://dx.doi.org/10.2320/matertrans.MAW201510

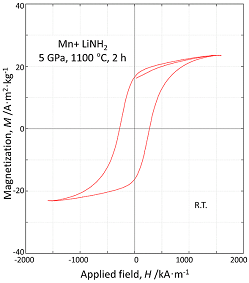

High-Pressure Synthesis of New Magnetic Compound in Mn-Li-N System

A new magnetic compound in the Mn-Li-N system was synthesized at GPa-order pressure. This compound had a body-centered-tetragonal (bct) structure (space group: I4/mmm, No. 139) with lattice parameters a = 0.29186 nm and c = 0.39108 nm. The saturation magnetization and coercivity of a sample synthesized under 5 GPa at 1100 °C for 2 h were 17.73 A·m2/kg and 310.7 kA/m, respectively.

- Itsuki Matsushita, Atsunori Kamegawa, Satoshi Sugimoto.,“High-Pressure Synthesis of New Magnetic Compound in Mn-Li-N System”, Materials Transactions., 57(10), 1832-1836, (2016).

http://dx.doi.org/10.2320/matertrans.M2016096

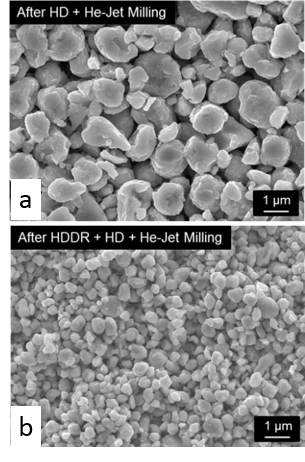

Development of Nd-Fe-B Ultrafine Powders Comparable to Single Domain Size

Decreasing grain size of the Nd2Fe14B phase is an established method for increasing coercivity of Nd-Fe-B sintered magnets. We decreased the size of jet-milled powder to around 1 μm by He jet-milling (He-JM) in Dy-free Nd-Fe-B sintered magnets and obtained high coercivity (μ0HcJ) of 2 T with (BH)max of around 400 kJm-3. We also succeeded further decrease in the size to 0.3 μm by combining HDDR, hydrogen decrepitation (HD) and He-JM1,2

- M. Nakamura et al., Appl. Phys. Let., 103, pp. 022404, (2013).

http://dx.doi.org/10.1063/1.4813399 - M. Nakamura et al., Mater. Trans. 55, 1582, (2014).

http://dx.doi.org/10.2320/matertrans.MAW201402

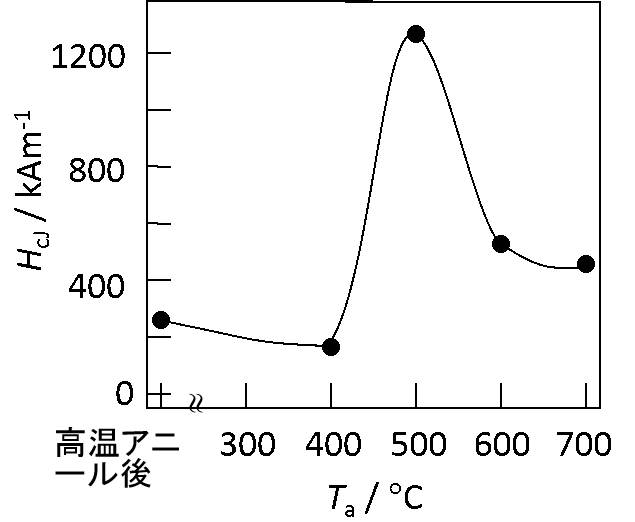

Development of New Mn-based Alloys with High Coercivity

No material which shows higher magnetic properties than Nd-Fe-B magnets has been found. However, we recently found that Mn-Sn-Co-N alloys show high coercivity comparable to rare earth magnets. (Fig. 1) The alloy showed high μ0HcJ of 1.59 T and two phase microstructure consisting of a perovskite phase and a β-Mn phase. TEM observation revealed that many twins were induced in the perovskite phase. It is considered that the microstructure is related to high coercivity.

- Keita Isogai et al., Mater. Trans., 54, 1236, (2013).

http://dx.doi.org/10.2320/matertrans.M2013113 - Keita Shinaji et al., Mater. Trans., 54, 2007, (2013).

http://dx.doi.org/10.2320/matertrans.MAW201312 - Masashi Matsuura et al., J. Alloys. Compd., 605, 208, (2014).

http://dx.doi.org/10.1016/j.jallcom.2014.03.158